Morpheus Tower Article in “The Structural Engineer”

After nearly 6 months of development, the big article on the Morpheus Tower Steel Connection Design came out to nearly 30,000 people worldwide today. I’ve learned so much through this process and have to thank big time Rob, Victoria, and Hayden for their guidance in writing this. I can’t give you a copy of the article because you’d need to pay for that with the IStructE, however, I can give you guys a quick intro to what we covered in the article.

Morpheus Tower Steel Connection Design Synopsis

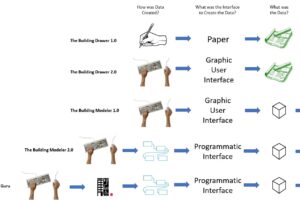

Steel connections are typically designed using well-established methods, developed from code-based rules, and are documented using standard drawing software packages. After careful deliberation it was decided ‘standard’ methods could not be used, or even adapted, for the exoskeleton connections due the highly irregular geometry and complex stress states that exist where members merge into the connections. BuroHappold concluded Finite Element Analysis (FEA) was the only viable alternative to verify their structural adequacy. It was also clear that normal software packages would not be readily useful to create the construction documents, especially for the free-form central region.

The global analysis model of the building was created using Midas structural analysis software but, due to the size and complexity of the building, it took 12 hours to run. Practically, this meant it was not viable to create and insert FE models of each connections into the global model as this would likely triple or quadruple the analysis time. The only practical alternative was to create separate ‘local’ models of the connections and transfer, or map, onto them the corresponding moments and forces from the global model results file, for all 105 load-combinations. This is not typically done as although FEA is a power analysis tool for engineers, the setup of such models is time intensive.

To complicate matters further, since the exoskeleton would be clad in aluminium, all connections and associated plates and bolts would need stay outside the cladding zone defined by the architect in a Rhino3d file. This, inevitably, would constrain and limit options for the geometry of the connections and necessitate non-planar solutions. To prove all our connection solutions stayed within into the cladding zone, in addition to creating FE analytical models of each connection, we would also need to create Rhino3d models of the outer surface geometry for a clash-detection study.

The tight construction programme demanded that all connection design, documentation and clash detection checks needed to be completed within 12 months. Given the 2500+ connections in the exoskeleton, we would need to complete an average of 50 per week.

To achieve the aggressive construction programme for the City of Dreams Hotel project, Buro Happold needed to develop a state-of-the-art approach for delivering the connection designs for the extremely complicated steel exoskeleton. This involved full FE analysis covering all 2500+ connections, with each unique type analysed using stand-alone ROBOT models, with forces/moments from all 105 loadcases in the global MIDAS model mapped onto them, and the whole process run using bespoke parametric software called Grasshopper, which integrated the MIDAS, ROBOT, Rhino3D and Excel software.

The Grasshopper scripts not only allowed the Buro Happold engineers to process vast amounts of data quickly but, importantly, they incorporated ‘on-screen’ visual checks at all stages of the process to help identify potential issues. The scripts were specifically designed to avoid being a so-called ‘black box’ set of tools, but rather, act as an extension of the Engineers hand; cutting-out mundane tasks and allowing more time to focus solving the extraordinary design challenges. This allowed for the design of over 350 unique exoskeleton connections to be designed ahead of schedule on the project with higher quality assurance that possible with convention methods.

For more on the Morpheus Tower Steel Connection Design, check out my submission video for the IStructE’s Young Engineer of the year award or this AIA seminar which we did with Zaha Hadid and Front.